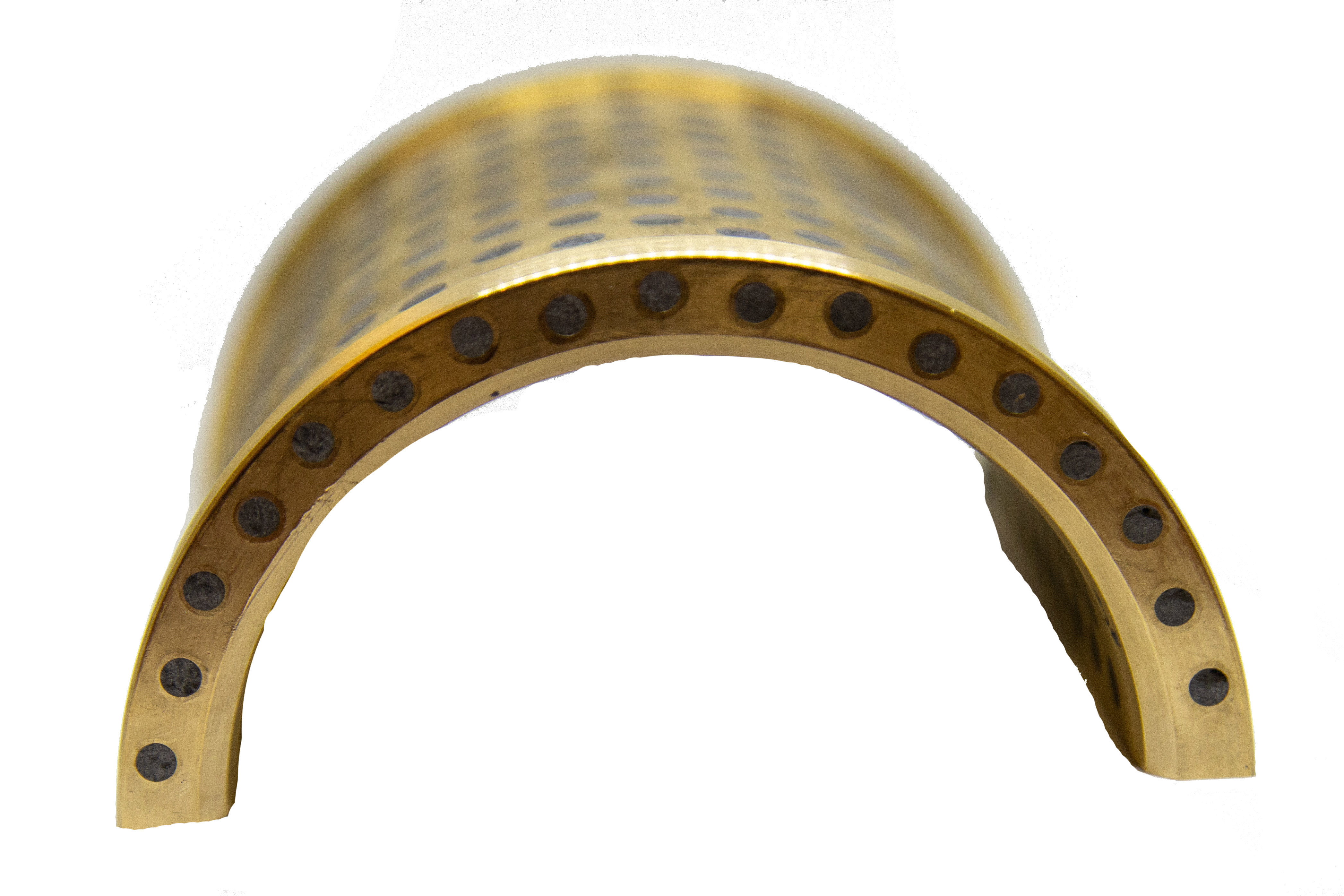

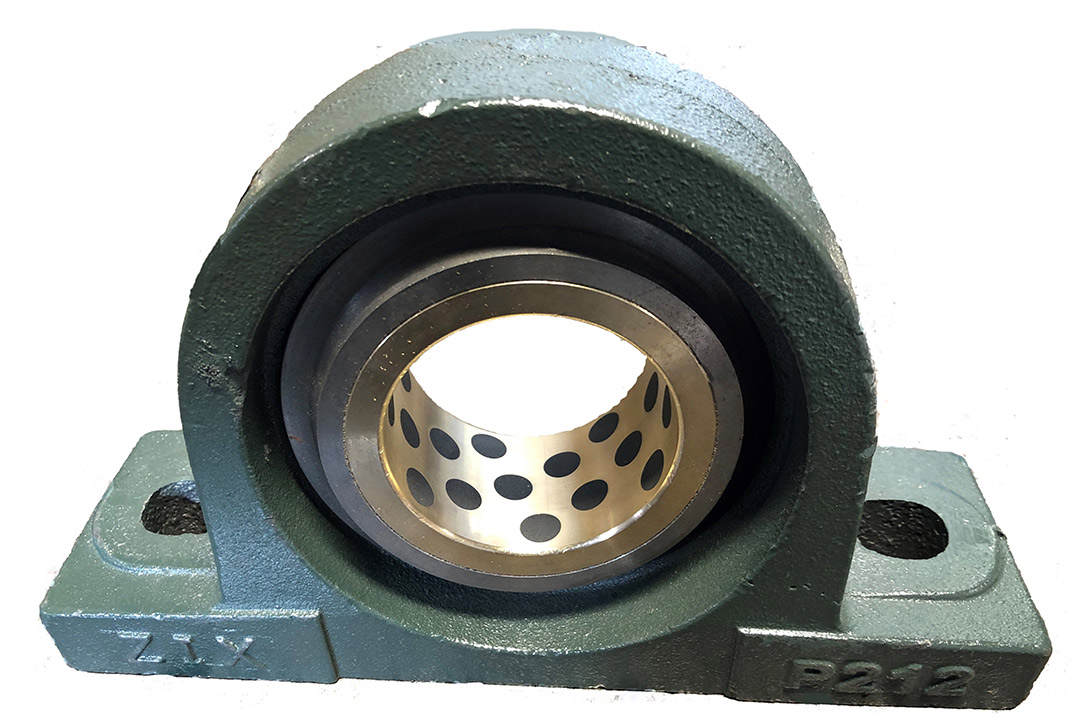

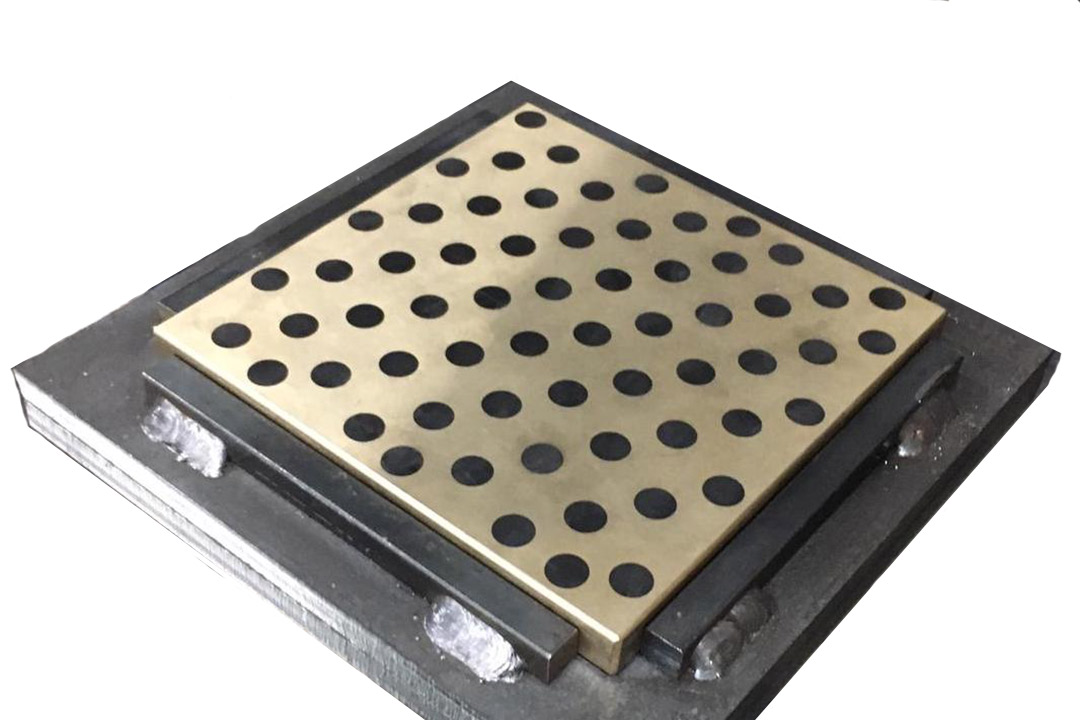

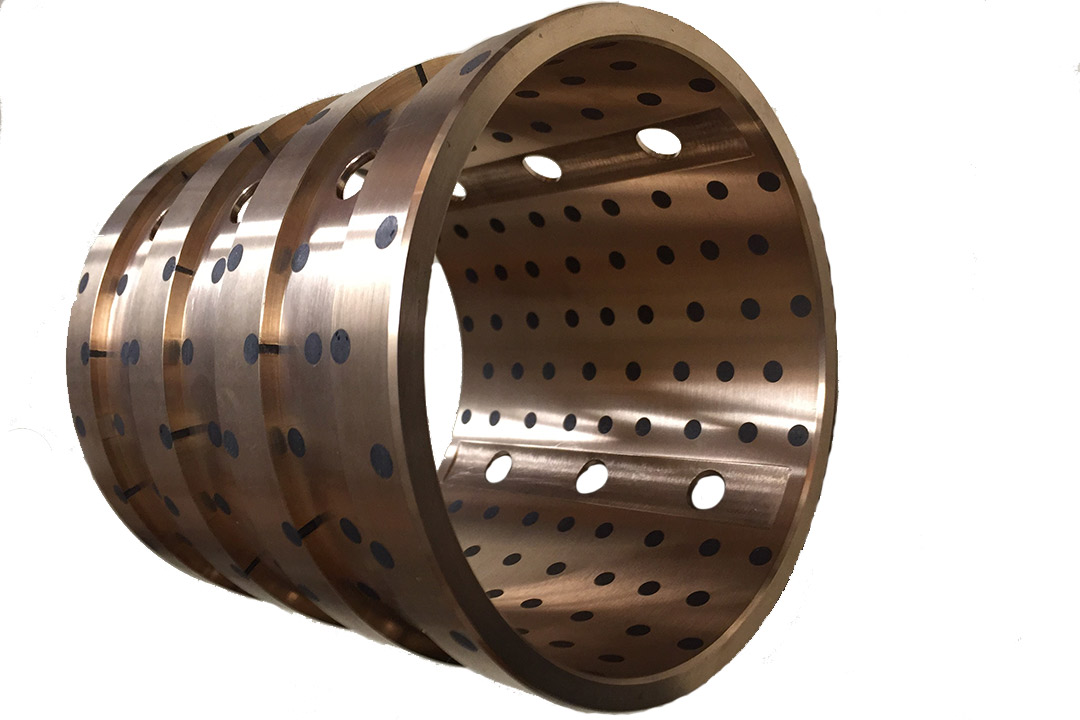

Self Lubricated Products

Available in a complete line of self lubricating bronze products that excel whenever standard lubrication is impratical. Especially in heavy load and high temperature applications. They come as sleeve bearings, washers, wear plates, and can be inserted into Pillow Block type housings.